PRATT Safety Showers and Eye Washes are made of high quality stainless steel and durable plastic materials for a long and dependable life. With a wide range including safety deluge showers, eyewashes, eye/face washes, portable, hand held and combination units, PRATT Safety Systems can provide you with strong and reliable equipment for any workplace requirements.

There are many things which can affect the supply to the equipment, please check the list below and refer to our minimum performance requirements on the product data sheet for your model.

• Adjust the flow control regulator to the eyewash.

• Check the eyewash aerators for any blockages.

• Check water supply piping size to the unit.

• Check flow rate and pressure of the water supply to the unit.

• Check the distance from the supply piping to the shower unit.

• Check the fluid supply is clean and lines were evacuated before install/use.

Check the unit for a Pratt sticker on the pipework/stanchion. Take a good clear image of the entire unit and push handle, then email info@prattsafety.com.au where we can assist in identification.

It is important to remember that eyewash stations and emergency showers are first aid treatment facilities and NOT hazard control measures. If workers are exposed to hazardous materials, you should always have other risk control measures in place, like isolation devices and personal protective equipment (PPE).

- Emergency eye wash equipment should be provided where there is a risk of hazardous chemicals or infectious substances causing eye injuries.

- Emergency shower equipment should be provided where there is a risk of:

• exposure to hazardous chemicals resulting in skin absorption or contamination from infectious substances, or

• serious burns to a large area of the face or body, including chemical, electrical or burns that are deep, in sensitive areas or larger than a 20 cent piece.

In the event of chemical contamination or burn to the body, arms, or legs, make your way to the Safety Shower as quickly as possible. Other people in the vicinity can aid the injured employee and call for further medical help.

- Activate the shower by pulling down the pull rod connected to the overhead shower.

- Stand beneath the flow, ensuring that the fluid flow is covering the body or affected area.

◦ Chemical Exposure: Remove all clothing, or items, which may be contaminated with chemicals.

◦ Fire/Burn: leave clothing in place unless advised to remove by a medical practitioner.

- Move around within the water flow, turning the body or limbs to aid the fluid coverage to the affected area.

- If your eyes are also injured, simultaneously activate the eyewash unit. Don’t allow water from the safety shower to enter the eyes as the higher pressure could cause irreversible eye damage. Refer to Eyewash operating instructions.

- Continue to flush the affected area for at least 15 minutes, or as directed on the recommendations of a medical practitioner and chemical manufacturer.

- Turn off the safety shower when completed flushing treatment.

- Seek further medical assistance from first aid trained personnel or medical centre if not already in attendance.

In the event of a chemical contamination or burn to the face or eyes, make your way to the Eyewash Station as quickly as possible. Other people in the vicinity can aid the injured employee and call for further medical help.

- Activate the Eye Wash Station by pushing the handle assembly or standing on the treadle, if fitted.

- Place your face and/or eyes centrally within the fluid stream:

◦ Chemical Exposure: Remove all clothing, or items which may be contaminated with chemicals.

◦ Fire/Burn: leave clothing in place unless advised to remove by a medical practitioner.

- Using your fingers and thumbs, hold open the eye lids to allow the fluid to wash around the eyes. Roll the eyes up and down and from side to side, making sure as much water as possible reaches the eyeballs.

- Remove contact lenses once flushing has begun (if possible), but don’t stop irrigating.

- If only one eye is contaminated, do not allow the contaminant to wash into the unaffected eye.

- Continue to flush the eye and/or face area for at least 15 minutes, or as directed by a medical practitioner and chemical manufacturer.

- Upon completion of water treatment turn the Eye Wash Station off by pulling the handle assembly to the off position.

- Seek further medical assistance from first aid trained personnel or medical centre if not already in attendance.

Emergency Shower & Eyewash Sign 450Mm X 300Mm Metal

Aerator Screen Assembly. Single & Triple Head Nozzles

New 316 Stainless Steel T Junction And Nipple Manifold

Stainless Steel Screws For Triple Aerated Eye & Face Wash Pk Of 10

.jpg)

Pratt Triple Eye And Face Wash Nozzle Housing

Stainless Steel Metering Screw Pack Of 1 - Flat

Stainless Steel Metering Screw Pack Of 1 - Tapered

Right Hand SS Braided Hose & Elbow Assembly For Showers

Left Hand SS Braided Hose & Elbow Assembly For Showers

Dust Cap Set - Red - For Single Eye Wash Nozzle New Style

316SS 15mm Ball Valve

Push Handle Horizontal Assembly

Foot Treadle Assembly

Pull Rod For Showers

Stainless Steel Shower Arm

Pratt Push Handle And Linkage Assembly Suits No Bowl Eyewash Unit

Stainless Steel Bowl Assembly

Dust Cover Cap For Triple Eye & Face Wash Nozzle Assembly

Dust Cover Caps For Single Eye Wash Nozzle Assembly Pk Of 2

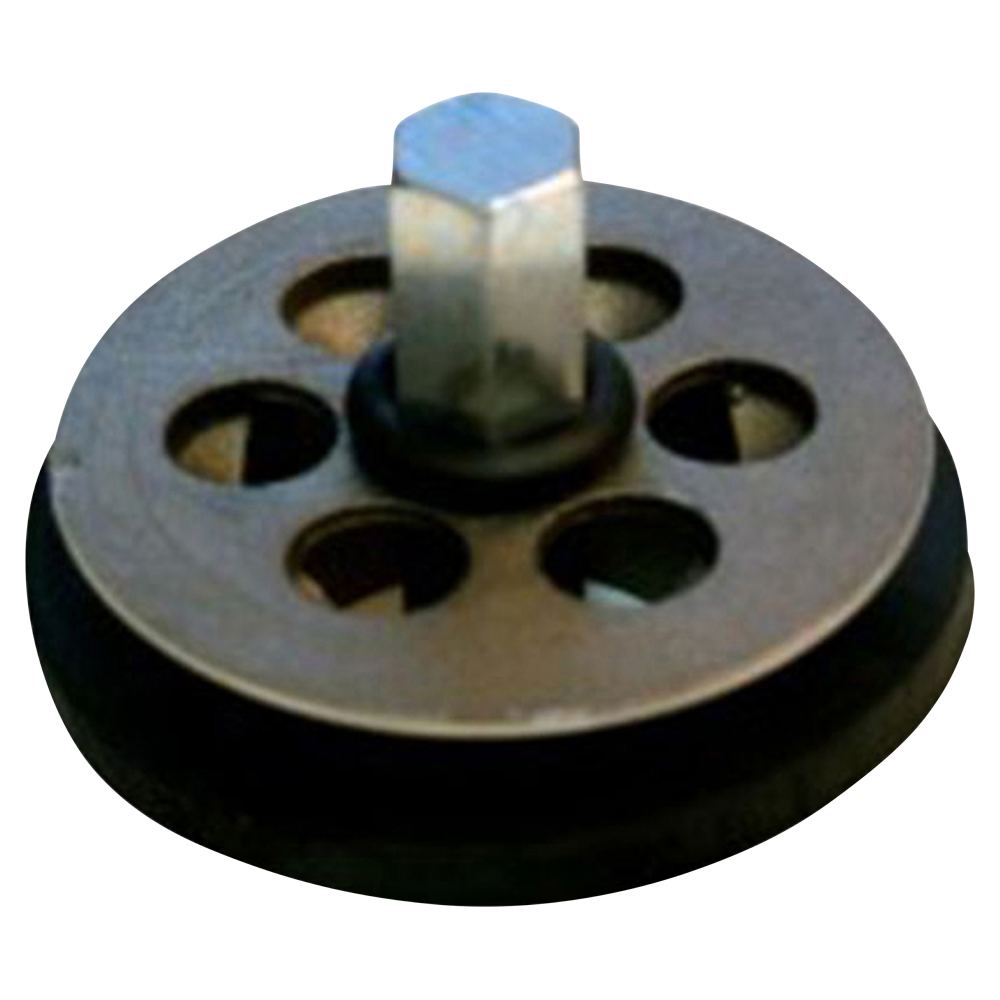

Drain Bowl Connector Kit